Enhanced Oil Recovery Compressor Solutions

Highly Engineered Solutions for EOR Compressors

By increasing injection pressures in enhanced oil recovery (EOR) processes, oil & gas producers can further boost production in mature wells.

Cook Compression pioneers highly engineered solutions to help OEMs and end users create new opportunities.

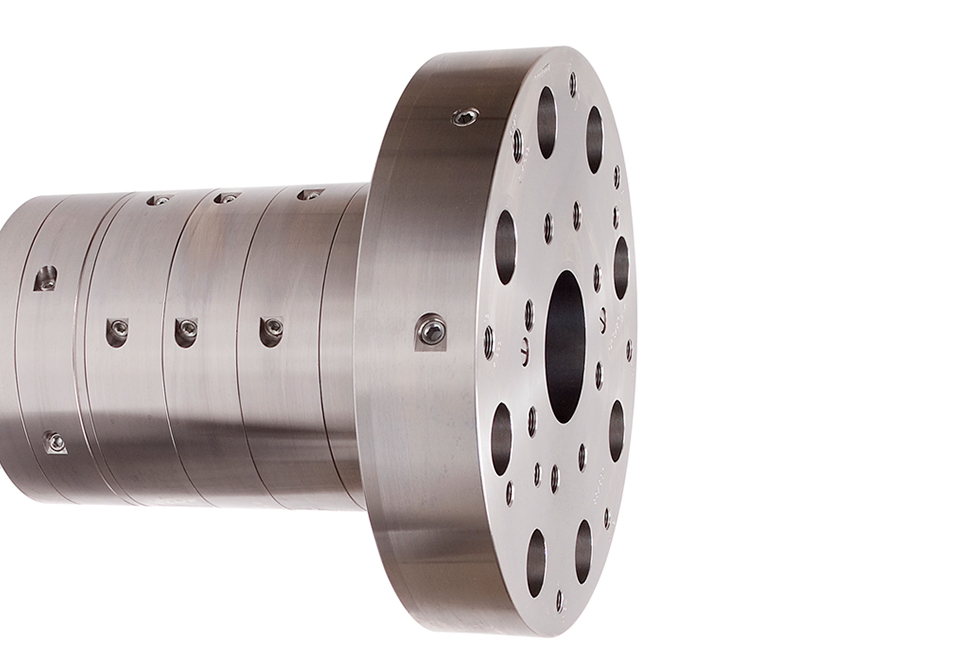

High-Pressure Packing Cases

Due to the extremely high pressures seen in EOR applications, special consideration must be given to protecting the structural integrity of packing case components and ensuring adequate sealing performance and life.

Applying a combination of carefully selected materials, proprietary product technology (such as Vortex Cooling® packing and gapless ring technology), and advanced engineering tools (such as finite element analysis), Cook has produced excellent performance in applications up to 12,000 psi (827 bar).

Custom-Engineered Valves

In CO2 injection processes specifically, compressor components must withstand liquid and potential corrosion. Cook Compression Manley® valves provide a smooth flow path for contaminants, while the valve body and springs are constructed from carefully selected alloys that exhibit resistance to wear and corrosion.

In addition, Manley valves are engineered to the needs of the application and can be equipped with the heavy springing required to handle high-density CO2 gas.

Project Services

As compressor operators maximize the capabilities of their reciprocating compressors, durability and efficiency are put at an even greater premium.

The Cook Compression projects group can deliver turnkey management of diagnostics, engineering studies, maintenance and life cycle improvements.

.png?fmt=png-alpha)