Hyper Compressor Components

Made for LDPE Service

To meet the demands of hyper compressors in low-density polyethylene (LDPE) service, Cook Compression engineers and manufactures a variety of high-performance parts in proprietary designs and metallurgies.

Partition Packing

Hyper compressor partition packing, which houses the media used to cool the plunger in the dynamic stage, is a critical component for equipment reliability. The packing must be designed to effectively prevent the cooling media from contaminating the system and prevent crankcase oil and high pressure packing lube oil from contaminating the cooling media.

Cook Compression’s range of high-performance designs and materials for scraper rings, pressure breakers, and gas sealing are an excellent fit for the rigorous demands of this packing. With design features such as side loading, interference fit with the plunger and near-zero leakage, Cook Compression provides effective sealing and wiping capabilities.

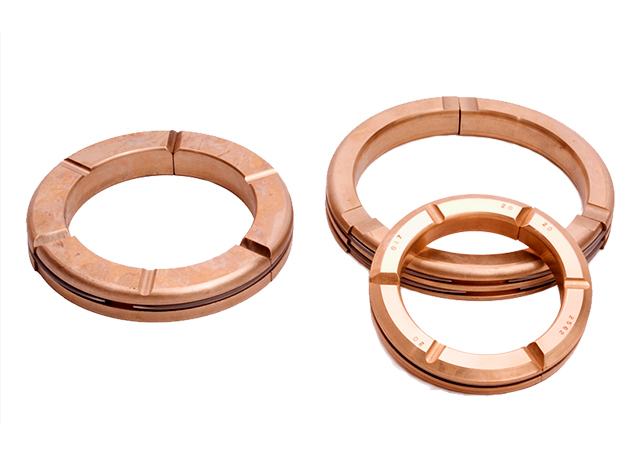

Specialized Bronze Rod Rings

Rod rings in specialized bronze grades are available in a variety of configurations for application throughout the partition packing. To ensure the highest-quality product, Cook Compression performs micrographic testing for lead distribution and hardness, with test samples kept on file.

Single-acting bronze pressure breakers effectively control gas flow, while seal rings in combinations of radial cut, tangent cut, and uncut rings form an effective seal against the rod. Depending on the ring configuration, leaded bronze, aluminum bronze and nonmetallic rings may be incorporated.

Complete Hyper Compressor Service

Cook Compression provides complete aftermarket service solutions for hyper compressors, including valve and packing case repair, plunger reconditioning, cylinder repairs, troubleshooting, and performance and reliability upgrades.

.png?fmt=png-alpha)