Packing Cases

Custom-Engineered Solutions

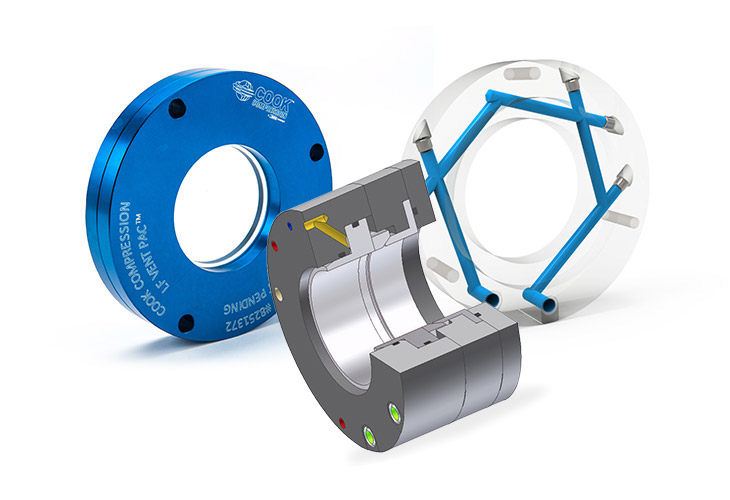

Cook Compression offers custom-engineered packing cases for any gas composition, at pressures ranging from vacuum to 50,000 psi (3,450 bar), in lubricated or non-lubricated service.

Advanced designs meet materials expertise to address your specific application needs. Features for venting and purging of gas are combined with specialty rings, control systems and/or standby seals to create high-performance emissions solutions.

Patented Low-Friction technology for purge and vent seals lowers rod temperatures and extends seal life. API 618-compliant cooled packing cases provide highly efficient heat transfer, as well as reduced leakage.

Packing Case Design

Each Cook packing case consists of a flange and a series of annular cups containing recesses for the packing rings. The type and material of the rings varies based on service conditions.

For up to about 2,000 psi (140 bar), the case material is normally cast iron, or Ni-Resist iron if the application involves corrosive gases. Steel or stainless steel is most common for higher pressures.

Specialty Designs

Vortex Cooling® Packing

Cook Compression Advantage

- Material options for all gases and pressure conditions, backed by in-house materials development

- Custom-engineered packing designed especially for your application

- Advanced hyper sealing components

- Cases for non-lubricated service

- Emissions-reduction options

.png?fmt=png-alpha)