Compressor Cylinder Repair Services

A Wide Range of Services

Wear, damage or changing operating requirements can prematurely shorten the service life of a compressor cylinder. Fortunately, expert repair and reconditioning can restore cylinders to original specifications, at a fraction of the time and cost of a new cylinder.

Cook Compression service centers perform a full range of cylinder services, including general repairs, relining and resizing, as well as reconditioning of unlined cylinders with advanced coatings. Our comprehensive cylinder refurbishing services are available for any type of reciprocating compressor.

A true turnkey resource, Cook Compression provides inspection and recommendations, machining labor, replacement parts, clearance tuning, hydro testing, recertification, sealing component upgrades, conversion to non-lubricated service and complete engineering support.

Complete Cylinder Repair Services

- Condition inspection and analysis

- Repair of damaged threads and cracks

- Restoration of face seal areas and valve seats

- Indicator port tapping for pressure monitoring

- Resizing

- Relining

- PlasKote50+® plasma coating

- Complete unit overhaul

- Turnkey low-density polyethylene (LDPE) cylinder reconditioning

- Clearance tuning

- Hydrostatic pressure testing

- Cylinder recertification

- Non-lube conversion

- Custom engineering and upgrades

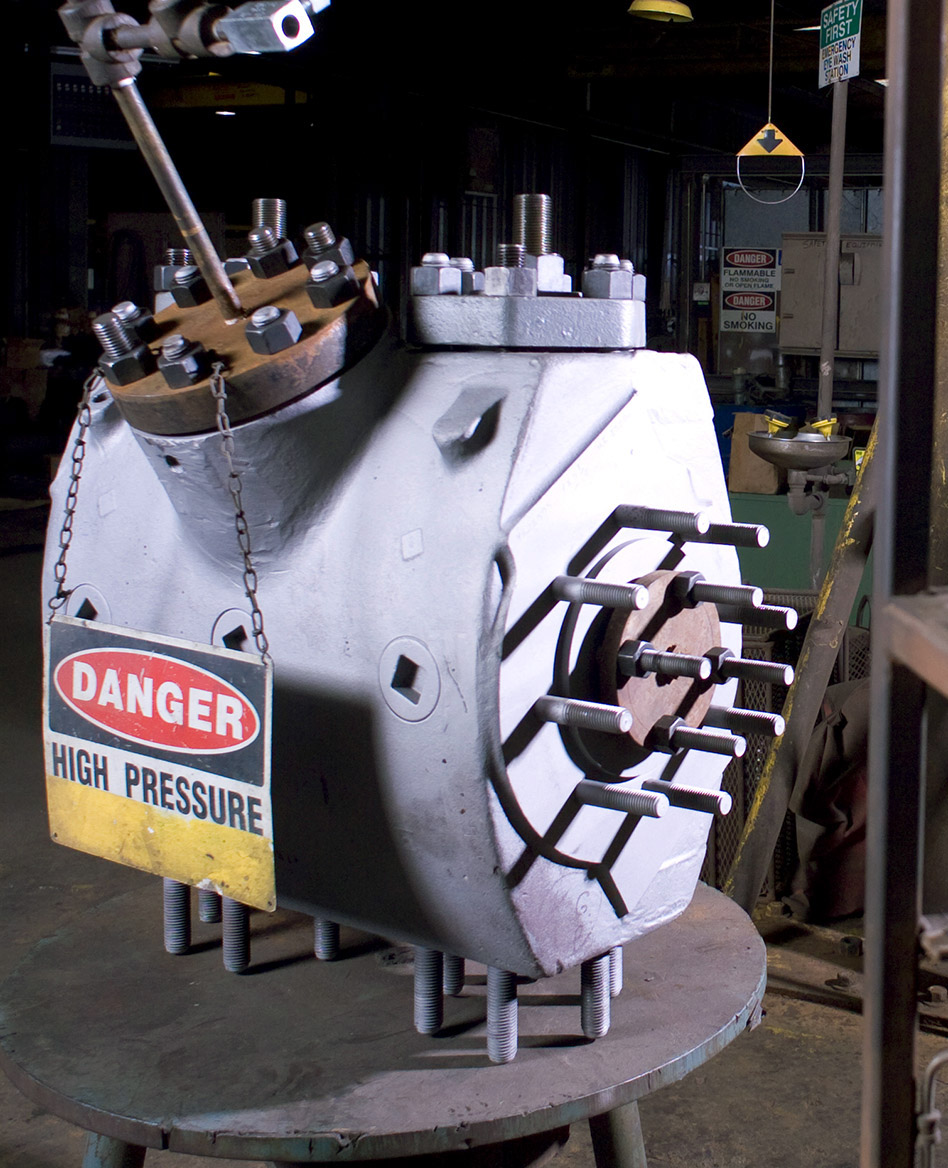

High-Pressure Applications

Among our specialties is repair and reconditioning of cylinders in LDPE and other high-pressure services. Experienced technicians perform complete disassembly, inspection, component replacement, reassembly and pressure testing.

PlasKote50+ Coating

PlasKote50+® coating is an effective way to recondition unlined cylinders without having to add a cylinder liner. It can be applied to any unlined cylinder, regardless of make or design, and allows your cylinder to retain its original pressure rating.

.png?fmt=png-alpha)