Compressor Valves

Increase Reliability and Efficiency

Cook Compression is an innovator in the design, manufacture and application of compressor valves. From precision-crafted metal plate valves to the latest high-performance designs with non-metallic internals, we offer solutions for any reciprocating compressor in any type of service.

Cook Compression manufactures complete valve assemblies, as well as plates, discs, rings, buttons, poppets, damper plates, spring plates, leaf springs and other metallic and non-metallic components for any make or model valve.

Valve Innovation

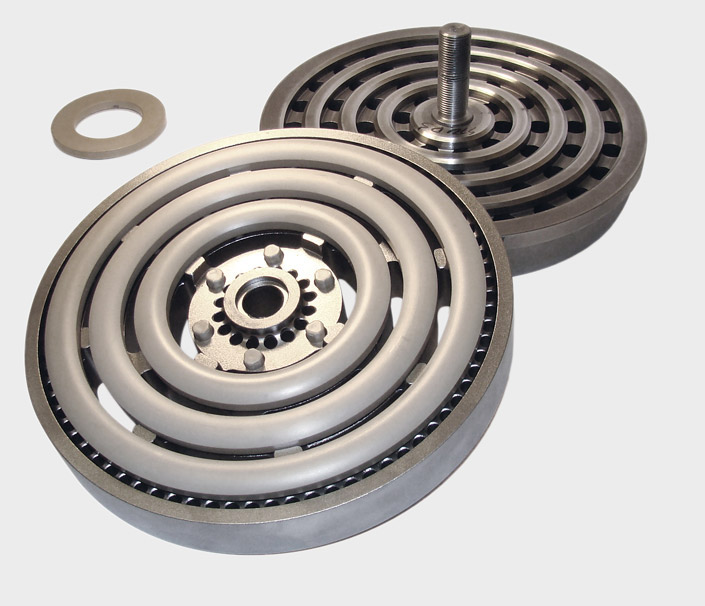

From the creation of the original radiused-disc Manley® valve to the extreme reliability of the patented MOPPET® valve, Cook Compression has pioneered developments in valve designs and materials that yield meaningful improvements in performance.

In 2015, we introduced the Ring Damped Valve for high-speed compressors, a groundbreaking technology that outperforms other valves in both run time and energy efficiency.

Elite Engineering

Our highly qualified in-house engineering teams use sophisticated 3D CAD modeling, linear and non-linear finite element analysis (FEA), computerized valve dynamics simulation and other proprietary engineering tools to design high-performing valves for your application needs.

Our expert staff includes engineers with compressor OEM experience, as well as materials scientists.

In addition to custom-engineering the products we make, Cook Compression can provide engineering services for valve analysis, upgrades and conversions.

Valve Designs

Multi-Element Valves

Ring Damped Valves

Plate Valves

Non-Return Valves

Manufacturing Excellence

Cook Compression manufacturing facilities use the most advanced automated equipment, including state-of-the-art CNC lathes, mills and laser metal cutting systems. Laser profiling and proprietary processes ensure stress-free metallic plates and discs.

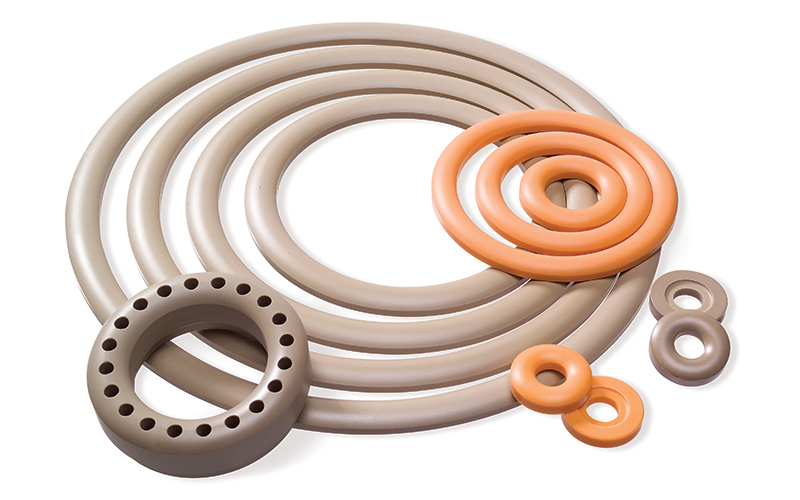

We also perform in-house injection molding of thermoplastic components. To ensure the purity and performance of finished parts, we use only 100% virgin material of the highest quality base resins.

Valve Materials

Depending on application requirements, Cook Compression uses filled and unfilled versions of PEEK, PPS and nylon for plastic valve components. Steel plate valve designs are also available.

Properties of the compressed gas, such as its chemistry, temperature and pressure, as well as application parameters of the compressor, such as its speed, determine the optimum material for each component.

Cook Compression Advantage

- Highly qualified engineering staff, including experts with compressor OEM experience

- Valve materials development program

- Advanced, computerized valve dynamics simulation

- Sophisticated 3D modeling and FEA

- In-house injection molding

- Stress-free metallic plates and discs

.png?fmt=png-alpha)