TruTech Engineered Polymer Materials

Superior Material Performance

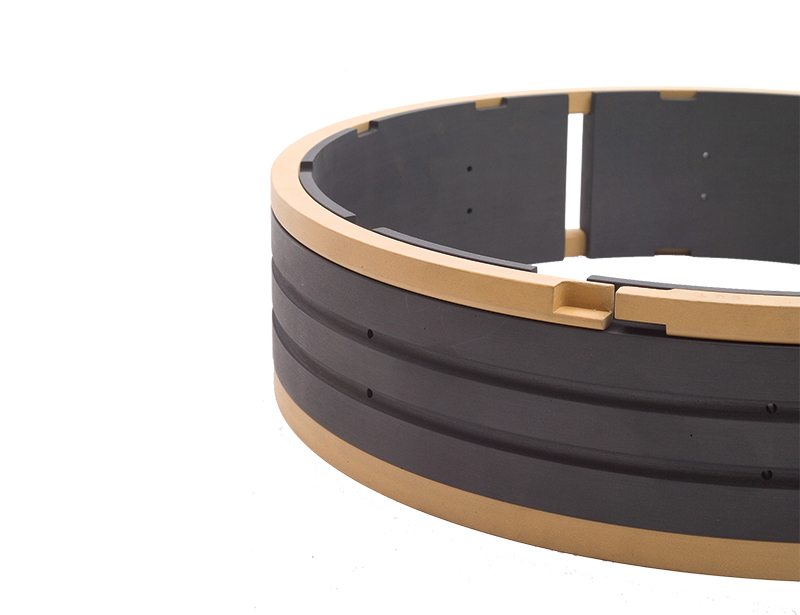

Incorporating the latest advances in polymer science, TruTech® materials from Cook Compression provide superior durability and optimum performance characteristics for reciprocating compressor components, including packing rings, wiper rings, piston rings and rider rings.

Proprietary Thermoplastics and Fluoropolymers

The TruTech family includes PTFE, UHMWPE, PEEK, PPS, polyimide and other high-temperature aromatic polymer materials.

Special formulations provide high-performance sealing and lasting reliability for even the most demanding non-lubricated, dry-gas and high-temperature applications.

Custom Formulations for Optimum Performance

In-house precision blending capabilities enable Cook Compression to enhance specific material properties using reinforcements, fillers and additives such as glass fiber, carbon, carbon fiber, graphite, metal powders, FDA-approved minerals, and molybdenum disulphide (MoS2).

Complete In-House Processing Capabilities

Cook Compression performs all compounding, compression molding, free sintering, injection molding and machining in-house. Processes are closely monitored to ensure the quality and consistency of finished products, and quality assurance procedures include full batch documentation.

Materials Development

The Dover Precision Components Materials Technology program integrates materials research with extensive engineering resources and more than a century of practical experience to develop next-generation polymeric materials and ensure the ongoing quality of our raw materials.

Broad in-house research and development capabilities enable us to control development from material composition through manufacturing process and product testing.

After a multifaceted analysis of material properties and assessment on in-house reciprocating wear testers, materials can be tested at product scale at the Dover Precision Components Innovation Lab.

Custom-Blended Materials

PTFE Materials

With its extremely low coefficient of friction, PTFE materials are the most common type of material used in reciprocating compressor piston, rider and packing rings.

PEEK Materials

Generally stronger than PTFE materials, PEEK materials are the second most common type of material for piston, rider and packing rings. They may also be specified for valve components in high-temperature environments.

PPS and Polyimide Materials

Polyimides are typically reserved for extreme, high-temperature applications. PPS is similar to PEEK and has broad chemical resistance.

Common Uses of Engineered Polymers

Custom-blended TruTech thermoplastics and fluoropolymers are used in a broad range of industrial applications and equipment.

Common uses include:

Bearings

Bellows

Bushings

Gaskets

Impellers

Piston rings

Rod rings

Seals

Sleeves

Spacers

Valve seats

Wear rings

Wiper rings

.png?fmt=png-alpha)