Vent Rings

Vent rings seal at the low-pressure end of the packing assembly to ensure that gas leakage is forced out of the vent connection rather than down the rod and into the distance piece. Cook Compression has long set the standard for effective vent ring performance in environmentally sensitive applications.

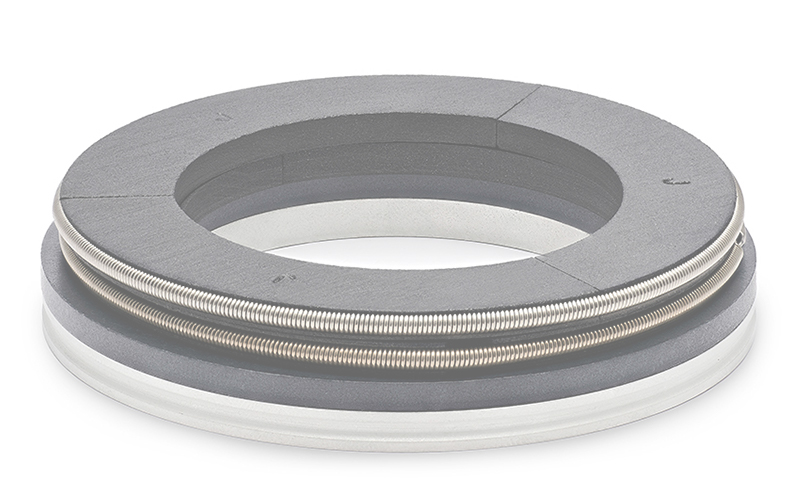

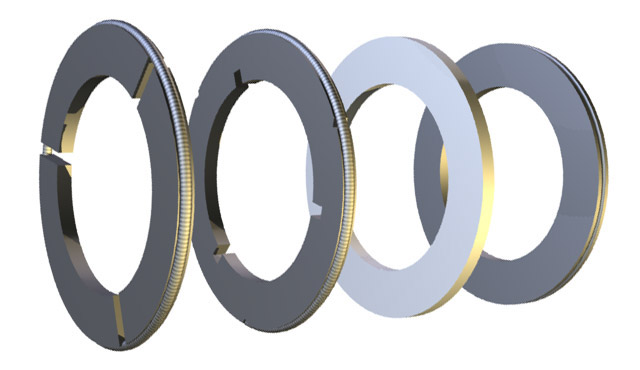

Featured Design: LF Vent Pac

.png?fmt=png-alpha)