Static-Pac Shutdown Seals

Lock in High-Pressure Gases

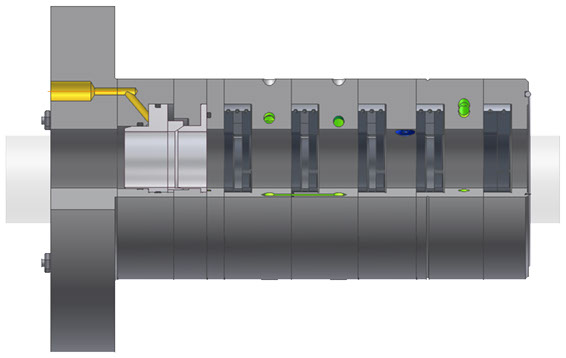

A Static-Pac® seal prevents escape of high-pressure gas from the packing case assembly during and after compressor shutdown.

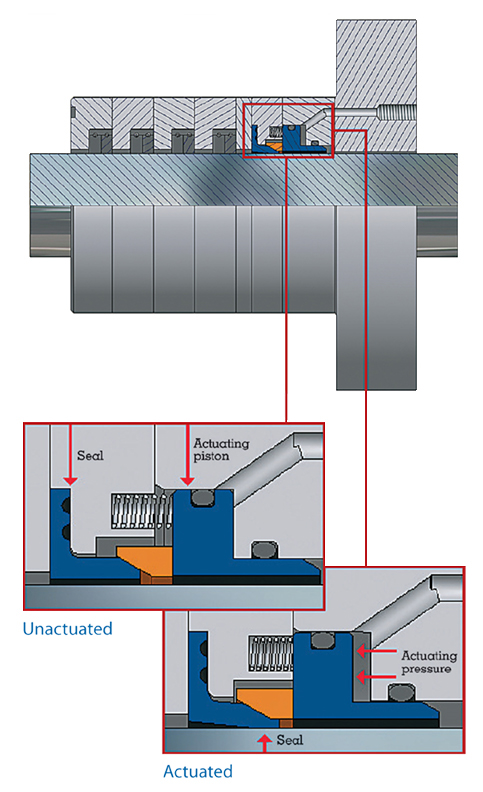

While conventional rod rings unload during shutdown, permitting high-pressure gases to escape, a Static-Pac assembly activates upon shutdown, mechanically wedging a lip seal tightly against the piston rod. The flexible polymer seal conforms to the rod circumference, locking in high-pressure gas.

When activating pressure is released during compressor start-up, the Static-Pac seal lifts off the rod surface to allow free movement of the rod.

Fast Payback

Static-Pac seals have demonstrated the ability to eliminate up to 96% of fugitive emissions.

While results for any given compressor will vary based on operating conditions and other variables, the payback for a Static-Pac seal is typically less than three years, and it will pay for itself many times over.

Increased Safety

Volatile and explosive emissions can accumulate and create health and safety hazards.

Static-Pac seals remove the pressure from ventilation systems, providing an extra layer of safety for the plant and personnel.

Environmental Protection

A study by the U.S. Environmental Protection Agency/Gas Research Institute concluded that 21% of all gas emissions within the natural gas industry come from reciprocating compressors.

Static-Pac seals can play a major role in reducing the release of greenhouse and other gases into the environment.

Simple Retrofit

Static-Pac seals can be retrofit to most gas compressor packing case assemblies and easily adapt to a wide range of compressor operating conditions. The assembly replaces one or two cups in the low-pressure side of the rod packing case.

Advantages

- Rapid payback with long-term savings

- Locks in valuable gases

- Improves safety

- Enhances environmental compliance

- Long service life

- Reduces downtime

- Retrofits to most packing cases

- No special maintenance required

.png?fmt=png-alpha)