Case Study

High-Performance Manley® Compressor Valve Solves Problems for Natural Gas Storage Facility

Compressor valve problems not only reduce the reliability of a machine, but also can restrict the productivity of an operation. This was the case for a North American natural gas storage facility that was struggling with poorly performing valves in a two-stage Ingersoll Rand KVR compressor.

The compressor has a 14-inch bore and 19-inch stroke. It operates at 335 rpm with a suction pressure of 720 psig and discharge pressure of 1,150 psig.

The unit could not be fully loaded because it was already running at the upper limit of its horsepower. Compressor valves in the first stage failed monthly, resulting in repeated downtime, maintenance expense and lost productivity. The customer contacted Cook Compression for recommendations.

The Manley Compressor Valve

Experts from Cook Compression analyzed the application and proposed replacing existing valves with custom-engineered Manley valves.

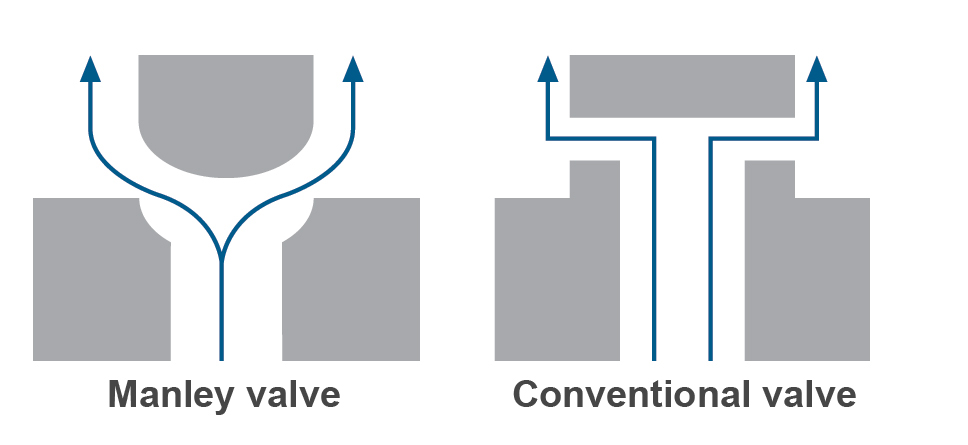

Radiused sealing elements in Manley valves deflect foreign matter in the gas stream for improved durability. They also promote aerodynamic flow of gas through the valve, resulting in reduced power consumption.

Conventional flat-plate designs force gas to make two 90° turns before passing through the valve. Any foreign materials in the gas must also follow this path. At 300 rpm, these materials have less than 1/10th of a second to pass through these turns. As a result, these foreign materials often squarely strike the valve plate at full speed and result in premature failure.

These same materials pass through the Manley valve with minimal impact on the radiused disc. Any remaining impact force is further compensated for by the resilience of the thermoplastic and the thickness of the Manley discs.

Payback Goal Achieved

The customer specified that the new valves must achieve a one-year payback, based on reliability increases, cost reductions from less-frequent valve reconditioning, and horsepower savings.

The Manley valve performance and cost savings far exceeded the customer’s requirements. The payback goal was reached in only two months, based solely on horsepower savings.

The compressor, which is used roughly three months out of each year, is now in its third year with the original set of Manley valves.

The Cook Compression solution also has helped the facility meet productivity demands. The Manley-equipped compressor is able to run fully loaded and is selected to run before any of the other machines at the facility because of its gains in efficiency and productivity.

Typical Applications

The Manley compressor valve provides extreme durability and improved efficiency in a broad range of applications, including:

Related Case Study

Manley Compressor Valve Tackles Varying Conditions at Gas Storage Plant

The use of a compressor for both storage and withdrawal created several sets of operating parameters for the compressor valves. Making conditions even tougher for the second stage valves, the compressor can run as either a single-stage or two-stage unit, depending on operational needs.

.png?fmt=png-alpha)