PPS and Polyimide TruTech Materials

Premier Materials for Extreme Applications

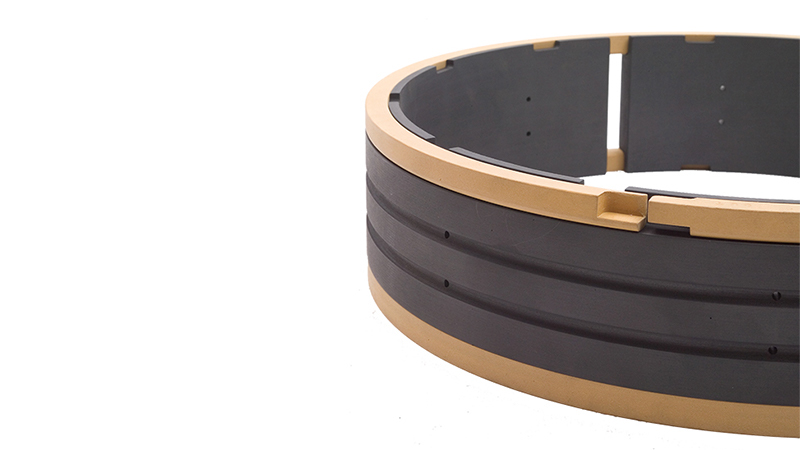

As part of its proprietary TruTech® materials line, Cook Compression produces specialty PPS (polyphenylene sulfide) and polyimide materials for select applications.

Polyimide Material Properties

Polyimides are typically reserved for extreme, high-temperature applications. Polyimides are resistant to most chemicals, except steam and ammonia, and exhibit excellent strength and wear resistance.

PTFE and graphite are typically used as fillers to reduce the coefficient of friction.

PPS Material Properties

PPS mechanical and wear properties are similar to those of PEEK. PPS has broad chemical resistance and is capable of running continuously at temperatures up to 220°C (428°F).

PPS is sometimes used as a filler to improve the wear performance of PTFE in piston, rider and packing rings.

More from Our TruTech Line

PTFE Materials

With its extremely low coefficient of friction, PTFE materials are the most common type of material used in reciprocating compressor piston, rider and packing rings.

PEEK Materials

Generally stronger than PTFE materials, PEEK materials are the second most common type of material for piston, rider and packing rings. They may also be specified for valve components in high-temperature environments.

Complete In-house Processing Capabilities

With in-house blending and processing capabilities, Cook Compression has the flexibility and expertise to deliver custom solutions tailored for maximum performance in your applications.

.png?fmt=png-alpha)